As the climate crisis becomes increasingly severe, sustainable energy solutions has become a top priority. As products of biomass pyrolysis and carbonization, biochar and biocoal have gradually become hot spots for research and application. However, are biochar and biocoal the same? How should you choose between them when facing different uses? Read on to learn more about these two special pyrolysis products.

Similarities between Biochar and Biocoal

Same Raw Material Sources

Both biochar and biocoal come from biomass, such as agricultural waste (straw, rice husks, palm waste etc. ), forestry waste (sawdust, wood chips), and livestock and poultry manure and other renewable resources. Using these wastes as raw materials can help solve the pollution problem of agricultural and forestry wastes and reduce greenhouse gas emissions.

Pyrolysis in Biomass

During the production process, both biochar and biocoal involve pyrolysis or carbonization of biomass, which changes the characteristics of the final product by controlling temperature and oxygen content. Biomass pyrolysis refers to the process of heating biomass to a certain temperature under oxygen-deficient conditions to decompose it into gaseous, liquid and solid products. By adjusting the temperature, rate, pressure, reaction residence time and type of biomass of pyrolysis, the properties and yield of the final product can be regulated.

Carbon Fixation Capacity

Both have a certain carbon fixation effect, which can reduce carbon emissions and be environmentally friendly. Biochar can exist for hundreds to thousands of years after being buried underground, which is equivalent to sealing carbon in the soil, helping to slow down global warming. Although biocoal releases carbon dioxide when burned as a fuel, it can be considered to be one of the effective means to achieve carbon neutrality to a certain extent because its raw materials come from biomass that absorbs carbon dioxide through photosynthesis.

Energy Utilization

Both biochar and biocoal can be used as fuel to improve the utilization efficiency of biomass energy. Biocoal can directly replace coal as a fuel to provide energy with high calorific value. Although biochar has a low calorific value, it can also be mixed with other fuels to improve combustion efficiency. The gas and bio-oil produced by pyrolysis can also be used as energy.

Differences between Biochar and Biocoal

| Property |

Biochar |

Biocoal |

| Production Temperature |

300-700°C |

700-900°C (high-temperature pyrolysis) |

| Volatile Content |

High, with a certain porous structure |

Low, with fewer volatiles |

| Calorific Value |

Low to medium (approximately 15-25 MJ/kg) |

High (approximately 25-30 MJ/kg) |

| Hydrophilicity |

Strong, capable of absorbing water and nutrients |

Weak, hydrophobic |

| Biological Stability |

High, can persist in soil for a long time |

Burns to release energy, consumed in the short term |

| Application Scenarios |

Agriculture and environmental management, like soil improvement, enhancing soil fertility, pollutant adsorption, and carbon sequestration |

High-energy-density fuel, can replace coal in power generation, industrial combustion, and boilers |

Production Temperature

The production temperature of biochar is usually low, ranging from 300-700°C. Low-temperature pyrolysis helps preserve the organic matter and pore structure in biomass, making it more suitable for soil improvement and environmental remediation. Biocoal, on the other hand, is produced at a higher temperature, ranging from 700-900°C. High-temperature pyrolysis reduces the volatile matter in biomass and increases the carbon content, thereby improving its energy density and combustion performance.

Volatile Matter

Biochar has a high volatile matter and a rich pore structure, which makes it excellent in soil improvement and environmental remediation. Biocoal, on the other hand, has a low volatile matter and produces less smoke and pollutants when burned, making it suitable as a clean fuel.

Calorific Value

The calorific value of biochar is low to medium, about 15-25 MJ/kg, while the calorific value of biocoal is high, about 25-30 MJ/kg. The high calorific value makes biocoal an ideal substitute for coal.

Hydrophilicity

Biochar has a strong hydrophilicity and can absorb water and nutrients, which gives it a unique advantage in soil improvement and sewage treatment. During the pyrolysis process at a higher temperature, the volatiles in the biomass (such as water, organic acids, alcohols, etc.) are removed in large quantities. These volatiles are usually hydrophilic, and their reduction makes the surface chemical properties of biocoal more hydrophobic.

Main Application

The porous structure of biochar can provide a good living environment for microorganisms and help promote the health of soil ecosystems. Therefore, biochar is currently mainly used in agriculture and environmental governance, such as improving soil, increasing soil fertility, adsorbing pollutants, carbon sequestration, etc., and has been regarded as an effective negative emission technology (NETs). As a high-energy-density fuel, biocoal can replace coal in power generation, industrial combustion, boilers and other fields. In addition, biocoal can also replace coke in the metallurgical industry to reduce carbon emissions.

Biological Stability

Biochar has high biological stability and can remain in the soil for a long time, playing a role in carbon fixation and soil improvement. Biocoal releases energy after combustion and is consumed in a short period of time.

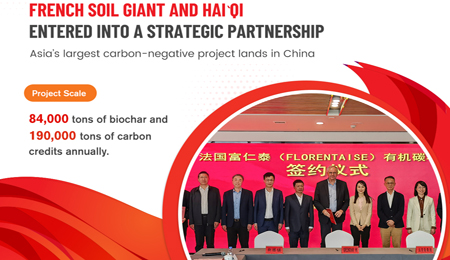

More than just the Biochar/Biocoal

Whether it's biochar or biocoal, they are both effective practice that people are doing to reduce their carbon footprint. At HaiQi, our biomass pyrolysis technology offers a unique solution. HaiQi’s pyrolysis equipment is not only fully customizable, but also offers the possibility of using the additional energy from the biomass pyrolysis process (waste heat and pyrolysis gas) to convert it into electricity. Throughout the process, the biochar production equipment can also be used to generate hot water or steam parallelly, or to generate heat to save on the cost of drying the biomass feedstock. On the road to net-zero goals, we'll always be a part of it. Are you considering biochar production or bio-coal production? Contact HaiQi's team of experts today to get your solution!