Operating Procedure of Biochar Pyrolysis Equipment

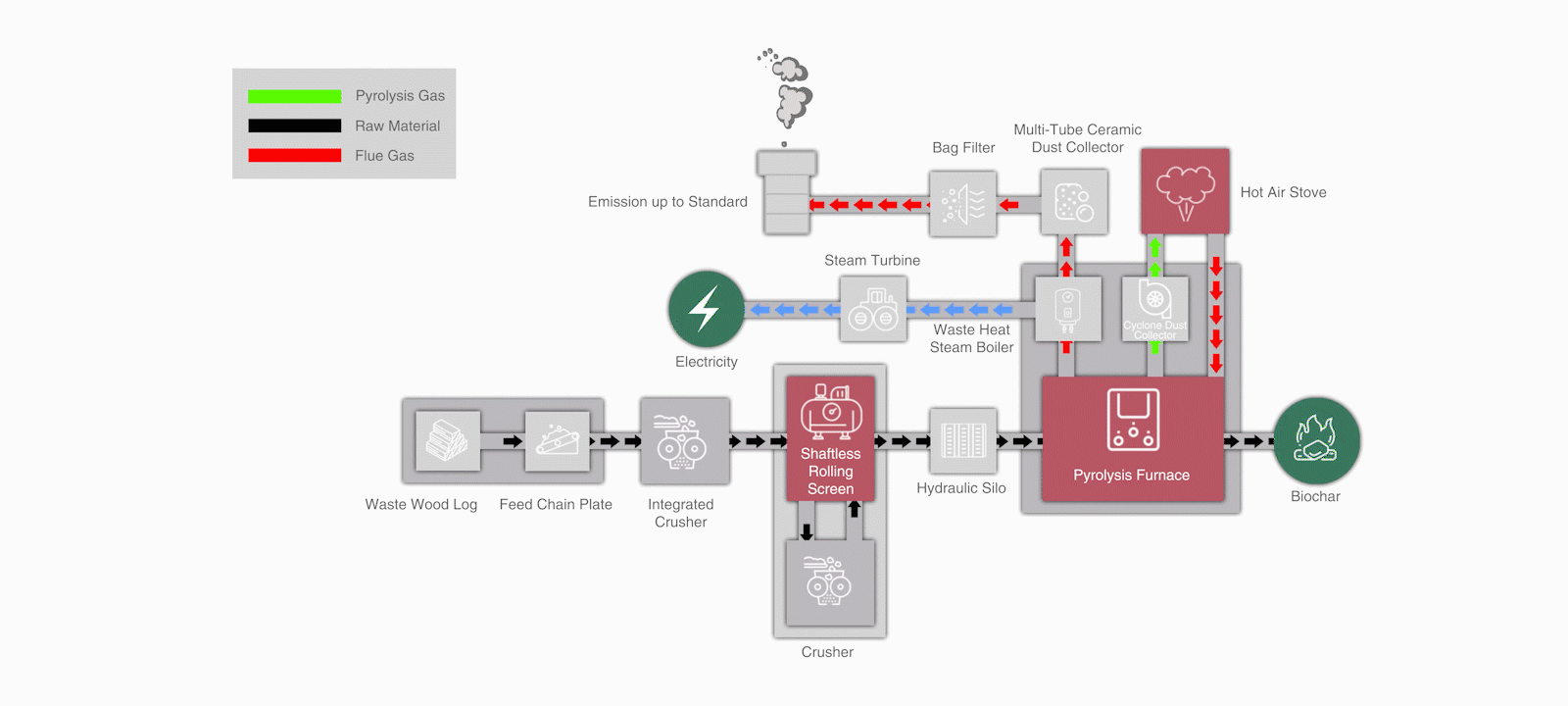

The core of the biochar pyrolysis equipment is the biomass pyrolysis furnace, and pyrolysis is its central step. Medium and high temperature pyrolysis is the core technology of pyrolysis carbonization equipment. The biomass feedstock is fed into the pyrolysis furnace, and is slowly heated to achieve carbonization, and finally produces biochar.

The specific workflow of biomass pyrolysis equipment is as follows:

In the early stages, we can use electricity, diesel, natural gas and other energy sources to start the equipment. After entering into stable operation, the waste heat and syngas generated during the pyrolysis process can be collected to drive the entire pyrolysis equipment and used for subsequent power generation or heat supply.

2. Does the heating rate affect the end product of pyrolysis?

During thermal pyrolysis of biomass, it can be mainly categorized into fast pyrolysis and slow pyrolysis depending on the heating rate. Under fast pyrolysis conditions, the pyrolysis oil accounts for the major portion; but for slow pyrolysis, the biochar accounts for a greater proportion compared to the liquid product.

The specific workflow of biomass pyrolysis equipment is as follows:

Pre-process the Feedstock

In order to accelerate the heating and full pyrolysis of feedstock, we need to crush and dry the feedstock first. Through pretreatment, the feedstock meets the feeding requirements (i.e. the size is <3cm, the humidity is <15%) and is fed into the pyrolysis furnace through the automatic feeder. If the feed humidity is greater than 15% but not greater than 50%, we can use the waste heat generated during the pyrolysis process to dry the feed.Heat Pyrolysis Furnace

Start the pyrolysis equipment with an igniter and preheat pyrolysis furnace. At this point, the pyrolysis furnace starts to rotate slowly to ensure that raw material inside the furnace is heated evenly. You need to be aware that you need to precisely control the rate of heating, not too fast and not too slow.Pyrolysis Progress

The pyrolysis furnace is heated to the range of 550°C - 600°C. The biomass feedstock undergoes thermal degradation in a closed and hot environment and forms a solid with a very high carbon content, which is called biochar. The pyrolysis progress lasts about 15-20 minutes. In addition to biochar, condensable liquids such as wood vinegar and wood tar, as well as gaseous products, are also produced in the pyrolysis process.Biochar Produced & Cooled

Since it has been in a closed high-temperature environment for a period of time, the surface temperature of the newly produced biochar is extremely high. Therefore, the biochar needs to be cooled before being discharged. When the temperature drops to a safe handling range, the biochar can be packaged, transported and stored. Depending on the final use of the biochar, auxiliary equipment such as biochar briquetting and granulation can be equipped.Exhaust Gas Treatment

The generated exhaust gas is discharged after filtering and dust removal, complying with the EU 2019 emission standards. This step effectively avoids additional exhaust gas treatment costs.FAQ

1. What fuel is required to run a pyrolysis plant?In the early stages, we can use electricity, diesel, natural gas and other energy sources to start the equipment. After entering into stable operation, the waste heat and syngas generated during the pyrolysis process can be collected to drive the entire pyrolysis equipment and used for subsequent power generation or heat supply.

2. Does the heating rate affect the end product of pyrolysis?

During thermal pyrolysis of biomass, it can be mainly categorized into fast pyrolysis and slow pyrolysis depending on the heating rate. Under fast pyrolysis conditions, the pyrolysis oil accounts for the major portion; but for slow pyrolysis, the biochar accounts for a greater proportion compared to the liquid product.

.jpg)