Explosion Proof Safety

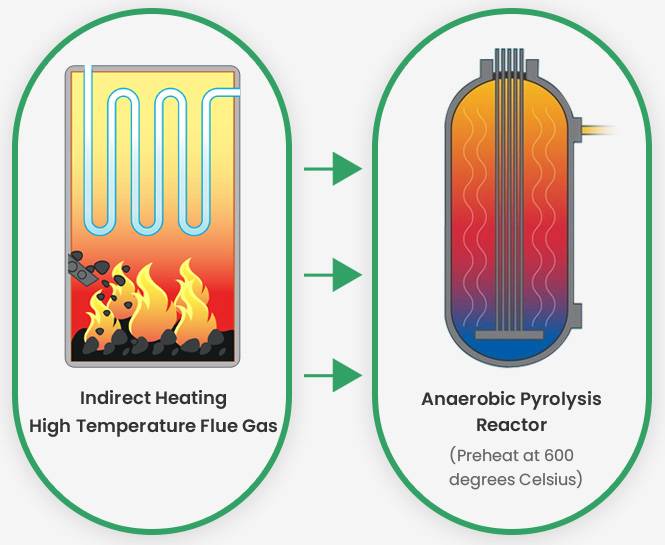

At the beginning of the system design, the earliest consideration is the safety of the system operation. The pyrolysis system is a single-channel rotary kiln with large volume, more biomass materials and combustible gases during operation, which has a huge risk of inflammable and explosive and CO poisoning for operators.

In the generation section of biomass gas, HaiQi began to adopt multi-point monitoring, pressure relief monitoring of combustible gas, emergency exhaust detection and control of combustible gas, concentration alarm of combustible gas.emergency closure monitoring of combustible gas after power failure, etc.