Haiqi Biomass Gasifier Project in Thailand

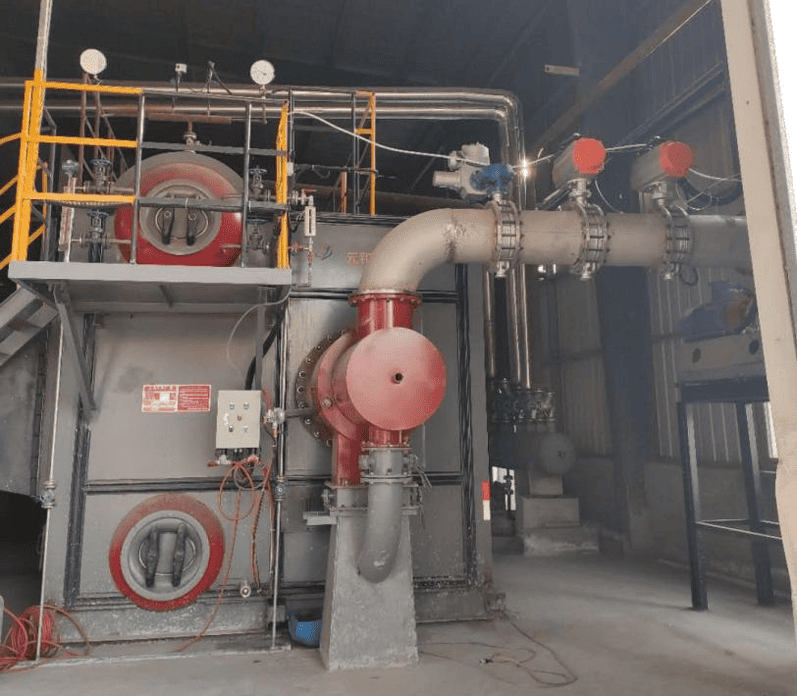

In 2020, Haiqi Group successfully built an energy-saving and highly efficient biomass waste gasification plant for a textile printing and dyeing factory in Thailand. The core equipment of this project is a set of 9 million kcal biomass gasifier, which is efficiently interfaced with a 15-tonne steam boiler.

In this project, Haiqi not only supplied the biomass gasifier and boiler, but also designed and implemented the tail gas treatment system, control system and combustion system. The syngas produced by the biomass gasifier is a kind of low calorific value gas. In order to ensure its stable combustion, Haiqi's technical team specially equipped it with a special burner and a special boiler. After flowing through the special burner, the combustible gas is stably ignited and enters the steam boiler to produce steam for the daily production of the textile printing and dyeing factory. The exhaust gas is then treated by a bag filter to ensure that it is discharged in compliance with environmental requirements. This customised gasification solution fully demonstrates the professionalism and reliability of Haiqi in the field of gasification.

It is worth mentioning that our client chose wood chips as the feedstock for the biomass gasifier, with a daily consumption of up to 90 tonnes and an annual operating time of more than 7,500 hours. Wood chips are burned in an oxygen-deficient environment to achieve pyrolysis gasification. During this progress combustible gases such as CO, CH4, H2, CmHn, etc. are produced, and the calorific value of these gases ranges from 1000-1300kcal. The produced combustible gases are discharged through the gas outlet at the upper part of the gasifier. The temperature is controlled within 200 degrees. At the same time, charcoal, also named biochar, is produced during the pyrolysis of wood chips. The biochar is discharged through an automatic slagging system at the bottom of the gasifier and is collected and can be sold for economic profit.

Haiqi has accumulated about 30 years of experience in the gasification field, and has successfully implemented more than 2,000 renovation projects globally. This project in Thailand proves once again Haiqi's professional ability and excellent quality in biomass energy utilisation. In the future, Haiqi will continue to devote itself to technological innovation and quality improvement to provide more customers with efficient and environmentally friendly biomass energy solutions. If you are considering replacing traditional fossil fuels with biomass, please do not hesitate to contact Haiqi, we are committed to providing you with the best energy saving and emission reduction solutions.

In this project, Haiqi not only supplied the biomass gasifier and boiler, but also designed and implemented the tail gas treatment system, control system and combustion system. The syngas produced by the biomass gasifier is a kind of low calorific value gas. In order to ensure its stable combustion, Haiqi's technical team specially equipped it with a special burner and a special boiler. After flowing through the special burner, the combustible gas is stably ignited and enters the steam boiler to produce steam for the daily production of the textile printing and dyeing factory. The exhaust gas is then treated by a bag filter to ensure that it is discharged in compliance with environmental requirements. This customised gasification solution fully demonstrates the professionalism and reliability of Haiqi in the field of gasification.

It is worth mentioning that our client chose wood chips as the feedstock for the biomass gasifier, with a daily consumption of up to 90 tonnes and an annual operating time of more than 7,500 hours. Wood chips are burned in an oxygen-deficient environment to achieve pyrolysis gasification. During this progress combustible gases such as CO, CH4, H2, CmHn, etc. are produced, and the calorific value of these gases ranges from 1000-1300kcal. The produced combustible gases are discharged through the gas outlet at the upper part of the gasifier. The temperature is controlled within 200 degrees. At the same time, charcoal, also named biochar, is produced during the pyrolysis of wood chips. The biochar is discharged through an automatic slagging system at the bottom of the gasifier and is collected and can be sold for economic profit.

Haiqi has accumulated about 30 years of experience in the gasification field, and has successfully implemented more than 2,000 renovation projects globally. This project in Thailand proves once again Haiqi's professional ability and excellent quality in biomass energy utilisation. In the future, Haiqi will continue to devote itself to technological innovation and quality improvement to provide more customers with efficient and environmentally friendly biomass energy solutions. If you are considering replacing traditional fossil fuels with biomass, please do not hesitate to contact Haiqi, we are committed to providing you with the best energy saving and emission reduction solutions.

haiqi biomass gasifier.jpg)

.jpg)