Biomass Pellet Burner Docking Boiler

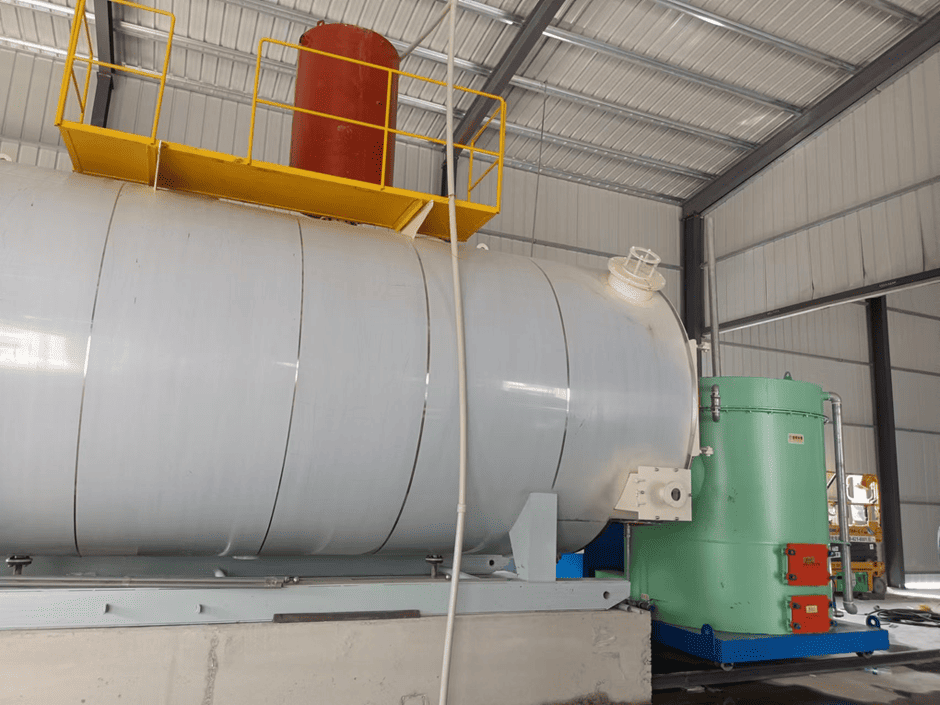

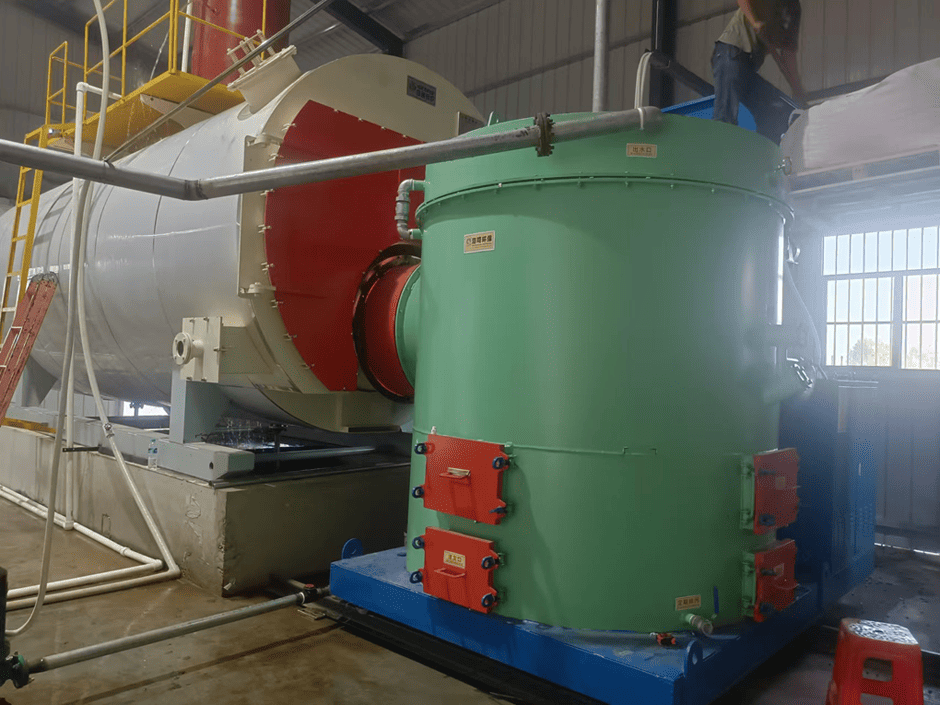

To cope with rising natural gas costs, a food factory plans to upgrade its factory boiler equipment. After the boiler factory recommended it, the customer decided to use Haiqi's biomass burner. In May 2024, Haiqi officially reached a consensus with this food company to develop and construct a project of connecting a 10-ton pellet burner to a 10-ton hot water boiler.

Overview

The customer uses standard 8mm biomass pellets as the feed material for the burner. After sampling testing, the fuel calorific value of the biomass pellets reached 4,200 kcal/kg. In order to meet customers' energy needs in different time periods, Haiqi's technical team designed a biomass pellet burner with a feed rate of 0.8 tons to 2.2 tons per hour to ensure the flexibility and adaptability of the equipment.

Configuration of Equipment

In the project, the customer used ton bags to directly distribute the materials, and imported the ton bags into the feed bin through a crane. The biomass particles enter the semi-gasification burner through the screw feeder for combustion. The flame generated by combustion enters the boiler furnace through scientific air distribution to ensure efficient heat exchange. The back end of the boiler is equipped with an energy saver for secondary recycling of heat to further improve energy efficiency. The back end of the energy saver is equipped with a multi-tube ceramic and bag dust collector. The flue gas undergoes secondary dust removal treatment before being discharged to ensure that the exhaust gas reaches the standard.

Cost Analysis

Initially, the customer planned to use natural gas as fuel, but after market research, it was found that the cost of natural gas is about 4.89 yuan per cubic meter. Especially in winter, the cost will increase significantly, putting pressure on production. After using the pellet burner produced by Haiqi, the customer saved about 50% of energy costs every month, and the savings are expected to be even greater in winter. According to the customer's own calculation, the project has successfully recovered the purchase cost only 4 months after adopting the pellet burner.

Since its founding in 1995, Haiqi has implemented more than 2,000 energy projects around the world and accumulated rich industry experience. In the future, Haiqi will continue to be committed to providing efficient and environmentally friendly energy solutions to more companies and promoting sustainable development. If you are considering energy upgrades, there is no doubt that Haiqi will be your reliable energy expert. Contact us today to get your energy solution!

Overview

The customer uses standard 8mm biomass pellets as the feed material for the burner. After sampling testing, the fuel calorific value of the biomass pellets reached 4,200 kcal/kg. In order to meet customers' energy needs in different time periods, Haiqi's technical team designed a biomass pellet burner with a feed rate of 0.8 tons to 2.2 tons per hour to ensure the flexibility and adaptability of the equipment.

Configuration of Equipment

In the project, the customer used ton bags to directly distribute the materials, and imported the ton bags into the feed bin through a crane. The biomass particles enter the semi-gasification burner through the screw feeder for combustion. The flame generated by combustion enters the boiler furnace through scientific air distribution to ensure efficient heat exchange. The back end of the boiler is equipped with an energy saver for secondary recycling of heat to further improve energy efficiency. The back end of the energy saver is equipped with a multi-tube ceramic and bag dust collector. The flue gas undergoes secondary dust removal treatment before being discharged to ensure that the exhaust gas reaches the standard.

Cost Analysis

Initially, the customer planned to use natural gas as fuel, but after market research, it was found that the cost of natural gas is about 4.89 yuan per cubic meter. Especially in winter, the cost will increase significantly, putting pressure on production. After using the pellet burner produced by Haiqi, the customer saved about 50% of energy costs every month, and the savings are expected to be even greater in winter. According to the customer's own calculation, the project has successfully recovered the purchase cost only 4 months after adopting the pellet burner.

Since its founding in 1995, Haiqi has implemented more than 2,000 energy projects around the world and accumulated rich industry experience. In the future, Haiqi will continue to be committed to providing efficient and environmentally friendly energy solutions to more companies and promoting sustainable development. If you are considering energy upgrades, there is no doubt that Haiqi will be your reliable energy expert. Contact us today to get your energy solution!

.jpg)

.jpg)